Agnes

Purpose - Tank internal Cleaning.

Tank Size ( diameter) – 20 <

Scope - Tank bottom; up to 2m of the side shell

Qty Manpower Required – Four (4)

1x Controller Operator

3x Manpower as auxiliary personnel, i.e. to operate the pump and other supporting equipment, and to assist the controller operator.

Features –

No Man entry.

Explosion proof and removes sludge through a separate suction pump.

Compatible with chemicals & high temperatures up to 60°C.

Samantha

Purpose - Tank Cleaning and paint removal

Tank Size ( diameter) – 30 <

Scope- Side shell of tank & tank bottom

Qty Manpower Required – Two (2)

1x Controller Operator

2x auxiliary personnel, i.e. to install Samantha inside the tank, operate the pump and other supporting equipment, and to assist the controller operator.

Features -

(After staff have installed robot inside tank)

Man-free method.

Light weight.

Ability to climb and wash side shell

Capable of washing using Ultra High Pressure of up to 40,000psi or 2,750bar

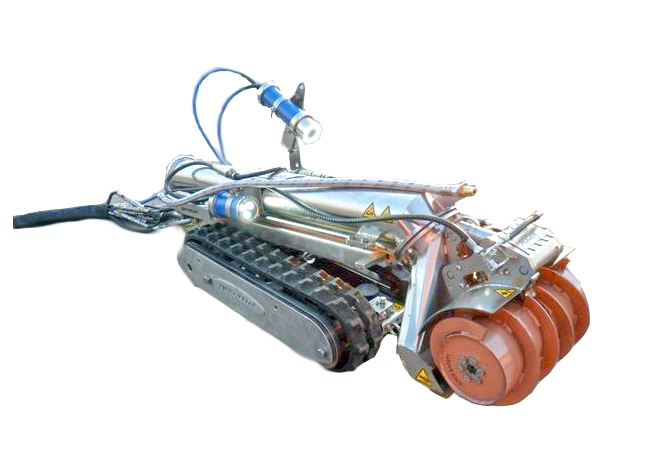

Fiona

Purpose - U/G or ISO Tank Cleaning

Tank Size ( diameter) - 10 >

Scope-Entire U/G or ISO tanks.

Qty Manpower Required – Three (3)

1x Controller Operator

2x auxiliary personnel to assist the operator in the set up and remove waste from the tank.

Features –

No Man entry.

Cleans and removes waste from the entire tank.

Compatible with chemicals.

Samantha

Purpose - Tank Cleaning and paint removal

Tank Size ( diameter) – 30 <

Scope- Side shell of tank & tank bottom

Qty Manpower Required – Two (2)

1x Controller Operator

2x auxiliary personnel, i.e. to install Samantha inside the tank, operate the pump and other supporting equipment, and to assist the controller operator.

Features -

(After staff have installed robot inside tank)

Man-free method.

Light weight.

Ability to climb and wash side shell

Capable of washing using Ultra High Pressure of up to 40,000psi or 2,750bar

Painting and Blasting

The maintenance of internals of tanks and good surface preparation is crucial because of the fact that the fuel and oil in the tank is expensive. To take a tank out of service to repair is very costly so you want to minimize the time between having to empty the tank to inspect it and repair it. So if you can decrease the time it means a massive cost saving to the facility and that’s what we are all about – reducing the cost of corrosion control. Good surface preparation is crucial to get excellent coating lift to minimize the maintenance time and out of service production costs associated with tank repair.